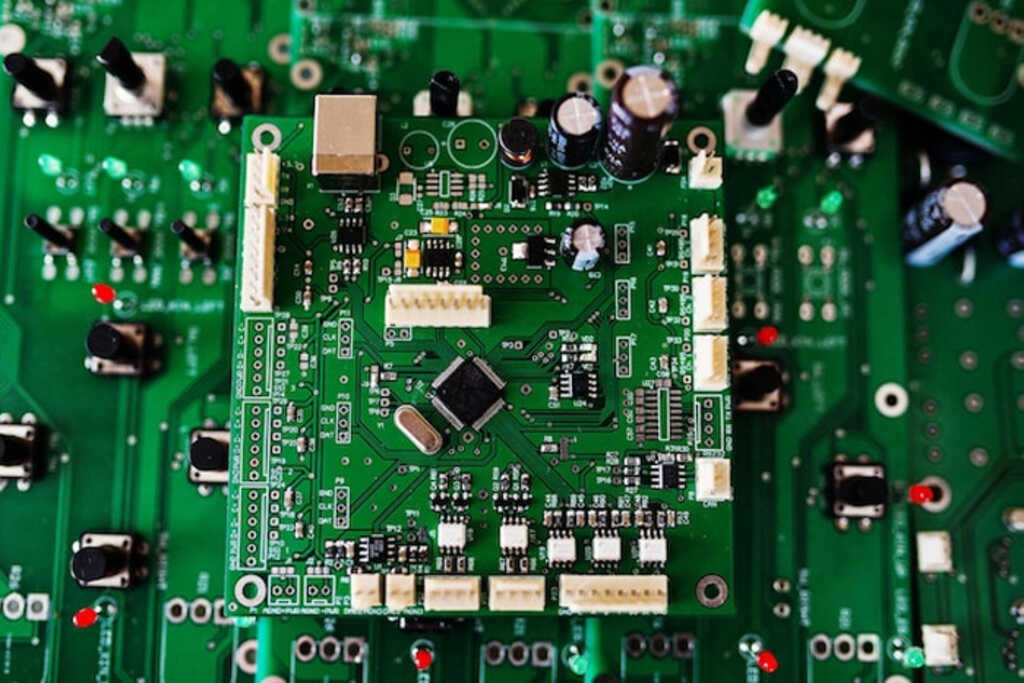

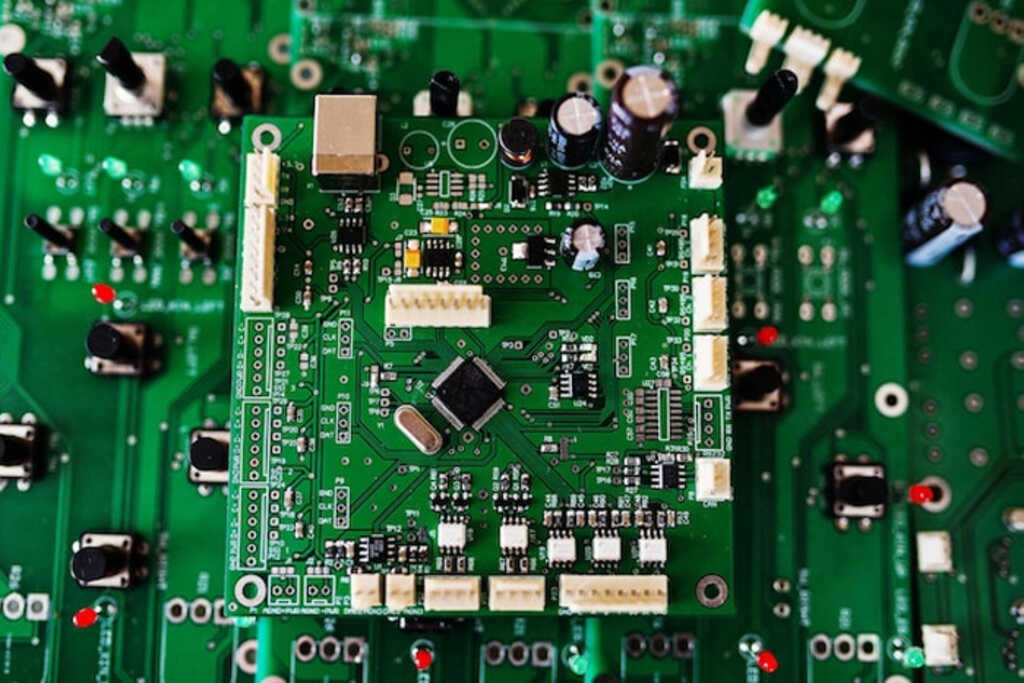

LCD controller board: key functions and applications

LCD controller boards play a crucial role in bridging the gap between display panels and embedded systems, ensuring seamless communication and efficient operation.

Whether used in industrial automation, medical devices, or consumer electronics, these boards simplify graphical user interface development and optimize the system performance.

In this article, we’ll explore the key functions, types, and applications of LCD controller boards, helping you choose the right solution for your project.

The LCD controller board market is continuously evolving, driven by industry 4.0 demands: More adoption of 4k/8K resolution panels, more demand for power-efficient controllers in portable devices, and a greater requirement for high-refresh-rate displays.

Keep reading!

How Does an LCD Controller Board Work?

An LCD controller board acts as the central processing unit for a display module, converting digital or analog signals into a format the LCD panel can interpret. In other words, it ensures proper synchronization between the display and the system’s processing unit, enabling seamless rendering of images, graphics, and text. The operation of an LCD controller board involves several key processes, such as signal conversion, frame buffering and rendering, backlight control, power management, touchscreen interface support and communication with external systems. One crucial aspect is timing control, which includes parameters such as pixel clock frequency, horizontal and vertical synchronization signals (HSync, VSync), and the data enable signal (DE). These parameters ensure that each pixel is updated at the correct time, preventing display artifacts. The frame buffer stores image data before sending it to the panel, with memory typically allocated within the controller itself or in external RAM. For backlight control, many controllers use Pulse Width Modulation (PWM) to regulate brightness efficiently, optimizing power consumption, especially in battery-powered applications. Power management ensures that voltage and current levels match the panel’s requirements, following precise power sequencing to avoid damage. Additionally, an LCD controller board interacts with external systems, such as microcontrollers, GPUs, or processors, via various communication interfaces, including SPI, I²C, UART, HDMI, and LVDS. These connections allow the board to receive display data, configuration settings, and touchscreen input, ensuring smooth integration with embedded systems. Accelerate your development with Proculus’ Starter Kit. A smart, cost-effective solution to kickstart your next project.What is the function of the LCD Controller Board?

The primary function of an LCD controller board is to bridge the communication between a display panel and a processing unit, ensuring that visual content is displayed accurately and efficiently. Key functions include:Interface management

The controller acts as a translator, converting the output from a microcontroller, GPU, or processor into a format that the LCD panel can display.Graphical processing

Some LCD controllers are equipped with built-in GPUs that allow for smooth transitions, animations, and high-resolution rendering.Display optimization

The controller regulates display settings such as refresh rate, contrast, and brightness, improving the visual output.User Interaction processing

If the display features a touchscreen, the controller processes touch inputs and relays them to the system’s main processor.Power efficiency management

Advanced controllers include features to minimize energy consumption, which is particularly important for battery-powered applications. Without an LCD controller board, integrating an LCD display into an embedded system would require complex programming and additional hardware, significantly increasing development time and cost.Main types of LCD Controller Boards

LCD controller boards come in various types, each designed to support different display interfaces and functionalities. Understanding these categories helps developers select the best fit for their specific applications. The primary types of LCD controller boards include:UART-Based LCD Controller Boards

UART (Universal Asynchronous Receiver-Transmitter) LCD controllers are widely used in embedded systems due to their simplicity and ease of integration. They communicate with microcontrollers via serial commands, reducing the need for complex programming. Proculus Technologies’ UART TFT LCD modules come with an intuitive GUI development environment, significantly reducing development time and effort.HDMI/DVI LCD Controllers

These controllers are designed for high-resolution displays and multimedia applications. They support full HD and 4K resolutions, making them ideal for digital signage, interactive kiosks, and entertainment systems. HDMI/DVI controllers are often used in computers, media players, and industrial visualization tools where high-quality visuals are required.VGA LCD Controllers

VGA-based controllers are common in legacy systems where analog signals are still in use. While not as advanced as HDMI or UART controllers, they provide compatibility for older devices that still rely on VGA connectivity. These are used in retro computing, industrial automation, and educational equipment where VGA output remains standard.Android-Based LCD Controllers

Advanced LCD controllers with built-in Android operating systems offer a highly flexible platform for GUI-based applications. These controllers feature powerful processors, allowing them to run full applications, handle touch interactions, and support Wi-Fi, Bluetooth, and USB connections. Android-based LCD controllers are popular in medical devices, self-service kiosks, and automotive infotainment systems, where an advanced and dynamic user interface is required.FPGA and Customizable LCD Controllers

Field-Programmable Gate Array (FPGA) LCD controllers provide high levels of customization for applications requiring specialized display protocols, high-speed data transfer, and real-time processing. These controllers are commonly used in military, aerospace, and high-end industrial applications, where performance, security, and customization are crucial.Applications of LCD Controller Boards

LCD controller boards are used in a wide range of industries, powering display solutions across different applications. Some of the most common use cases include:Industrial Automation and HMIs

Human-Machine Interfaces (HMIs) play a crucial role in industrial control systems, enabling operators to monitor and manage machinery efficiently. LCD controller boards in industrial applications ensure that real-time data visualization, process monitoring, and user interactions function smoothly. They are widely used in factory automation, SCADA systems, and industrial robots.Medical Devices and Diagnostics

The medical industry relies on high-resolution, accurate, and responsive displays to enhance patient care and diagnostics. LCD controller boards power ultrasound machines, medical monitors, infusion pumps, and laboratory analyzers, providing healthcare professionals with clear and easy-to-use touch interfaces.Consumer Electronics and Smart Devices

From smart home appliances to wearables, LCD controller boards are a key component in modern consumer electronics. They are used in smart thermostats, interactive kitchen appliances, fitness monitors, and multimedia systems, delivering smooth graphics, touch functionality, and seamless user interactions.Automotive Displays and Infotainment Systems

Modern vehicles are equipped with digital dashboards, infotainment centers, rearview monitors, and climate control interfaces. LCD controllers help manage these high-resolution screens, ensuring quick response times, crisp visuals, and efficient power consumption. Advanced touchscreen interfaces and gesture-based controls are also becoming standard in modern vehicles.Retail, Kiosks, and POS Systems

LCD controller boards are widely used in self-service kiosks, interactive menus, point-of-sale (POS) systems, and digital signage. Their ability to handle touch interactions, high-definition graphics, and real-time data processing makes them ideal for banking terminals, ticketing systems, and retail checkout displays.Aerospace and Defense

High-performance LCD controllers are used in cockpit displays, military-grade navigation systems, and mission-critical control panels. These applications require rugged, highly reliable, and fast-processing displays that can withstand harsh environments and extreme conditions.Key factors that differentiate LCD Controller Boards

When choosing an LCD controller board, several factors can influence performance and suitability. Read the following to understand more:Need for custom Firmware

To ensure that LCD controller boards can work in harmony with specific LCD panels, each controller board needs to be equipped with custom firmware. Firmware is a software program embedded on the controller board responsible for configuring its functions and ensuring compatibility with a particular LCD panel. The importance of firmware lies in its inclusion of crucial information needed for communication and control with the LCD panel. This information includes LVDS interface configuration, resolution settings, color calibration, power specifications, and more.

Support for different LVDS interfaces

The LVDS interface is one of the most critical components of an LCD controller board. LVDS is a digital signal transmission standard used to transmit image and video data from the controller board to the LCD panel. However, different LCD panels may use different types of LVDS interfaces, contributing to the diversity of LCD controller boards. Various LVDS interfaces can have different numbers of pins, varying pin layouts, and distinct electrical characteristics. Therefore, the controller board’s LVDS interface must perfectly match the LVDS interface of the LCD panel to ensure that data can be correctly transmitted and displayed on the screen. These differences also encompass the protocol and data rate of LVDS signals. That is, different types of LCD panels may require specific protocols and data rates to function correctly, and this information must be included in the firmware of the controller board. Read more: What Are the Types of LCD Screens and How Are They Classified?Varying power specifications

Another crucial aspect is the power requirements of LCD panels. Different LCD panels may require varying voltage and current levels to drive pixels and backlighting. Consequently, LCD controller boards must provide the appropriate power specifications to ensure the LCD panel operates correctly. Some LCD controller boards offer adjustable power outputs, which can be configured based on the requirements of the connected LCD panel. However, this still requires the correct firmware to ensure that the power supply aligns with the LCD panel’s specifications.Compatibility with specific features and functions

In addition to basic functionality, some LCD controller boards support specific features and characteristics, such as:Touchscreen support

Some LCD controller boards come with touchscreen control functionality, allowing users to interact with the display through touch. This requires additional hardware and firmware support.Color calibration

Some LCD controller boards support color calibration to ensure accurate color representation, which is particularly important in professional applications.Multi-Screen Support

Certain controller boards allow the connection of multiple LCD panels to create large-screen displays. This requires specific hardware and firmware support. These additional features are typically used in conjunction with specific LCD panels and, therefore, require customized firmware support. While LCD technology is widely used across various devices, LCD controller boards are not all the same.Count on Proculus’s help for your project

When it comes to developing high-quality display solutions, Proculus Technologies has you covered. Whether you’re integrating a UART TFT LCD module for seamless microcontroller communication, exploring the differences between LCD controller boards, or looking for a reliable HDMI display solution, we provide the tools and expertise you need. Our innovative products simplify GUI development, reduce engineering time, and enhance the user experience—allowing you to focus on what truly matters: bringing your vision to life. Let Proculus be your trusted partner in display technology. Explore our complete range of display solutions and take your project to the next level with Proculus Technologies!Conclusion

An LCD controller board is a vital component for any embedded system requiring a graphical interface. Understanding the technical specifications of these boards, their functional capabilities, and the key differentiators can help you make more informed choices when selecting the right solution. By leveraging the right LCD controller board, developers can reduce integration complexity, enhance user experience, and accelerate product development. Whether you’re building an industrial HMI, a medical device, or a smart home application, choosing a high-quality LCD controller board is essential for ensuring optimal performance and reliability. For a hassle-free solution, Proculus Technologies provides ready-to-use UART TFT LCD modules and professional services that streamline that streamline development and enhance product design.

Category:

Author:

Client:

Date:

PHP Code Snippets Powered By : XYZScripts.com

English

English