Understanding SMD and Its Role in Reliable Hardware Design

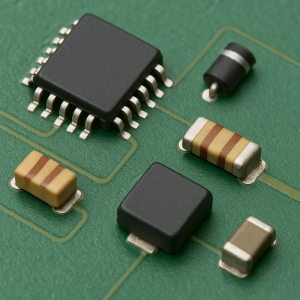

What are SMD Components?

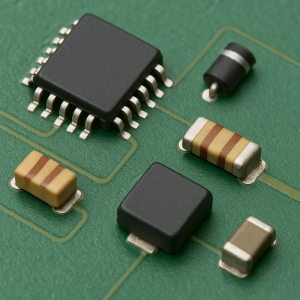

SMD (Surface Mount Device) components are electronic parts designed to be mounted directly onto the surface of printed circuit boards (PCBs).

Unlike traditional components that require holes to be drilled through the PCB, SMD parts are soldered directly to the surface, allowing for more compact, efficient, and automated assembly.

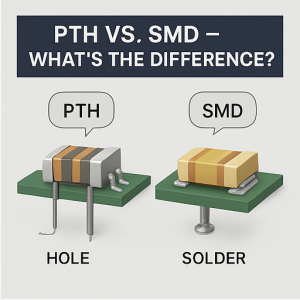

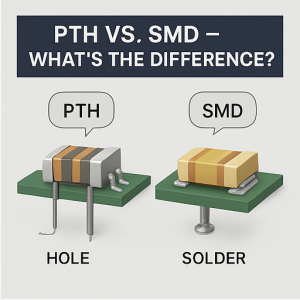

PTH vs. SMD – What’s the Difference?

PTH (Plated Through-Hole) components are inserted into holes drilled through the PCB and then soldered from the opposite side. While PTH offers strong mechanical bonds and is useful in certain high-stress applications, it requires more space and manual assembly.

In contrast, SMD components enable higher component density, smaller device profiles, and full compatibility with automated production lines. This not only improves manufacturing efficiency but also reduces the overall size and weight of electronic devices.

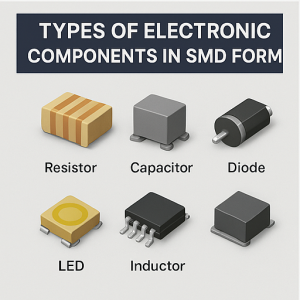

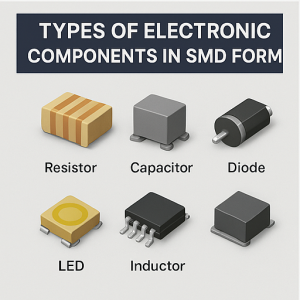

Common Types of SMD Components

SMD technology is applied across virtually all standard electronic parts. Common SMD components include:

- Resistors (e.g., 0805, 0603 packages)

- Capacitors (e.g., MLCCs in 0402, 0603 sizes)

- Diodes and LEDs

- Transistors and MOSFETs

- Integrated Circuits (ICs) such as microcontrollers and memory chips

- Inductors and crystal oscillators

These components are typically labeled using standardized codes and follow industry-recognized packaging sizes that ensure consistency across manufacturers and applications.

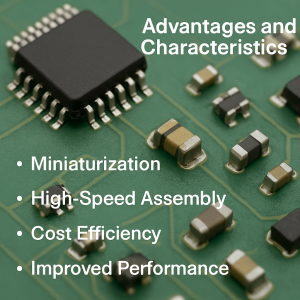

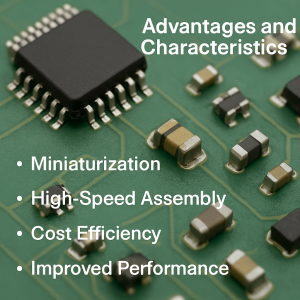

Advantages of SMD Components SMD parts offer numerous benefits:

- Miniaturization: Ideal for compact and lightweight product designs.

- High-speed assembly: Compatible with automated pick-and-place and reflow soldering.

- Cost-efficiency: Lower production costs due to streamlined assembly.

- Improved performance:Shorter lead lengths reduce parasitic inductance and capacitance, improving electrical performance.

- Design flexibility: High component density enables complex multi-layer board designs.

How to Identify an SMD Component? SMD components are typically labeled with alphanumeric codes that indicate their value, tolerance, or function.

For example, resistors may be marked with a three- or four-digit code indicating resistance value, while ICs often have manufacturer logos and part numbers printed on top.

Additionally, each component type follows a standardized package code (e.g., SOIC, QFN, BGA) that defines its footprint and lead configuration.

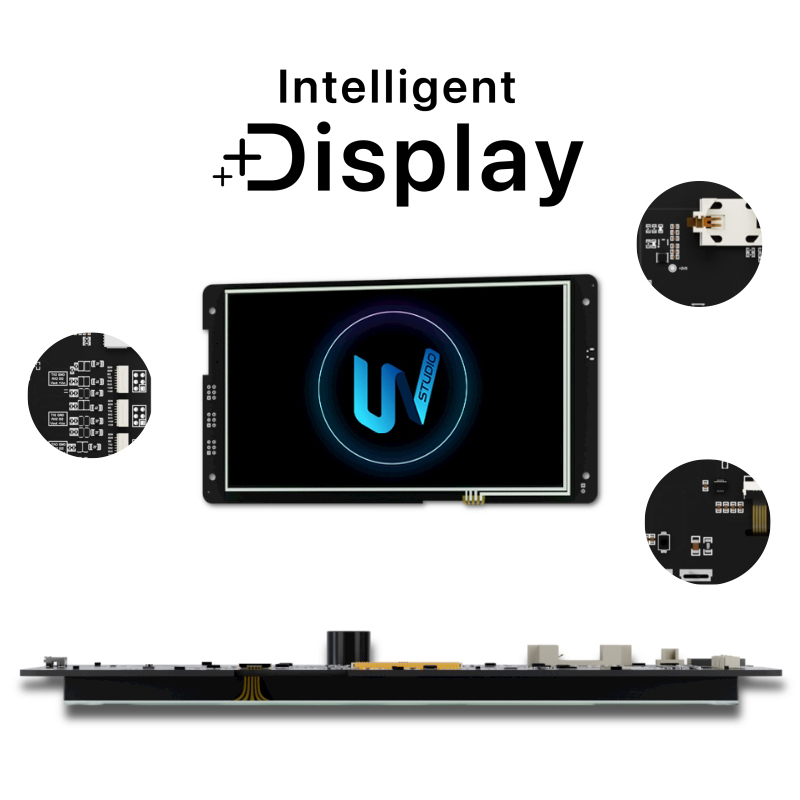

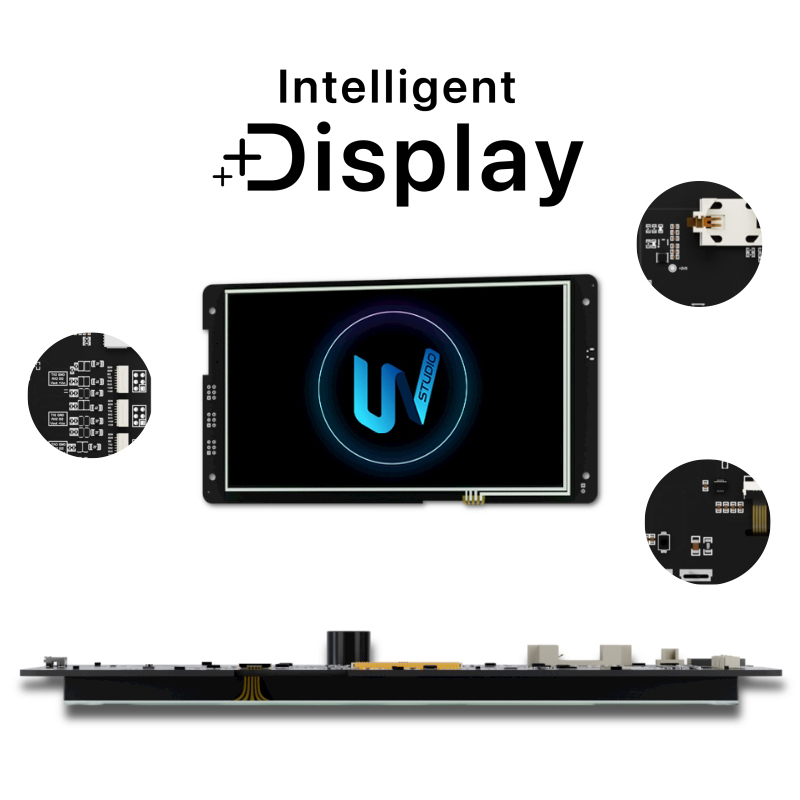

SMD in Our Products – Reliable Performance from the Inside Out

At Proculus, we prioritize quality and precision in every detail of our hardware. All of our Smart Display Modules/TFT LCD Modules utilize high-quality, industrial-grade SMD components to ensure stable and reliable system performance.

Our PCB back-panel design and production processes are crafted with meticulous attention to electrical integrity, thermal management, and long-term durability.

Recently, we’ve further enhanced our smart display product line with improvements in both SMD layout and overall hardware architecture. These optimizations allow for greater cost-efficiency and superior application performance, without compromising on stability or quality.

By leveraging advanced SMD technology and high-end PCB design principles, we continue to deliver display modules that meet the rigorous demands of industrial, medical, and commercial applications—where reliability isn’t optional, but essential.

Keep paying attention to us and we will show you more new displays!

Category:

Author:

Client:

Date:

PHP Code Snippets Powered By : XYZScripts.com

English

English